30 RPM Center Shaft Metal Gear DC Motor

30 RPM Center Shaft Metal Gear DC Motor

- Stock: In Stock

- Brand: Generic

- SKU: RM000791

Product Highlights

- RPM: 30.

- Operating Voltage: 12V DC

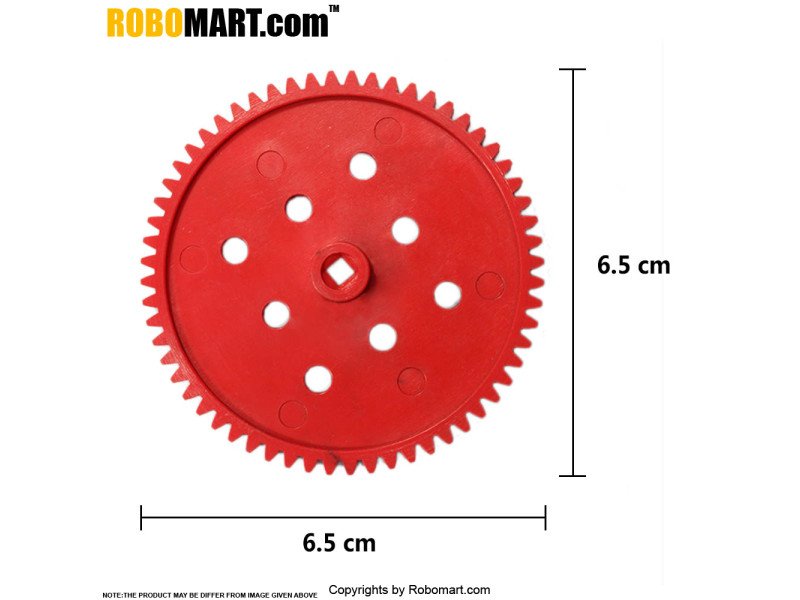

- Gearbox: Attached Plastic (spur)Gearbox

- Shaft diameter: 6mm with internal hole

- Torque: 2 kg-cm

- No-load current = 60 mA(Max)

- Load current = 300 mA(Max).

A 30 RPM DC Geared motor gives the mechanical throughput of 30 RPM.

A DC Geared motor is a simple DC motor with gear box attached to the shaft of the motor which is mechanically commutated electric motor powered from direct current (DC)

Construction of Center Shaft Gear Box:

On opening the outer plastic casing of the gear head, gear assemblies on the top as well as on bottom part of the gear head are visible.. A strong circular imprint shows the presence of the gear that rotates the gear at the upper portion. The cap that accommodates the gear has an arc cut from its side to avoid frictional resistance forces with the bottom gear assembly. The bottom houses the gear mechanism which is connected to the DC motor through screws. This mechanism rotates the gear at the top which is connected to the rotating shaft.

The gear assembly is set up on two metallic cylinders whose working can be called as similar to that of an axle. A total of three gears combine on these two cylinders to form the bottom gear assembly out of which two gears share the same axle while one gear comes in between them and takes a separate axle. The gears are basically in form of a small sprocket but since they are not connected by a chain, they can be termed as duplex gears in terms of a second cog arrangement coaxially over the base. Among the three gears, two are exactly same while the third one is bigger in terms of the number of teeth at the upper layer of the duplex gear. The third gear is connected to the gear at the upper portion of the gear head. After the gear assembly is removed, gear head’s connection to the DC motor and its gear can be easily seen. The machine has a smaller gear in comparison to the gear head’s gear assembly.

Working of Center Shaft Gear Box:

The working of the gears is very interesting to know. It can be explained by the principle of conservation of angular momentum. The gear having smaller radius will cover more RPM than the one with larger radius. However, the larger gear will give more torque to the smaller gear than vice versa. The comparison of angular velocity between input gear (the one that transfers energy) to output gear gives the gear ratio. When multiple gears are connected together, conservation of energy is also followed. The direction in which the other gear rotates is always the opposite of the gear adjacent to it. In any DC motor, RPM and torque are inversely proportional. Hence the gear having more torque will provide a lesser RPM and converse.

₹ 188.80 (Inc GST)

₹ 188.80 (Inc GST)

₹ 212.40 (Inc GST)

₹ 188.80 (Inc GST)

₹ 165.20 (Inc GST)

₹ 188.80 (Inc GST)

₹ 188.80 (Inc GST)

₹ 199.42 (Inc GST)

₹ 81.42 (Inc GST)

₹ 57.82 (Inc GST)