-

All Categories

-

Electronic Components

- Bread Board and Zero PCB60

- Capacitor0

- Crystal Oscillators0

- Diodes0

- Electronic Switches Button and Keypads212

- Fuse and Holders0

- Heat Sinks30

- IGBT13

- Inductor0

- LEDs and Indicators0

- Magnet0

- Microcontroller ICs113

- MOSFETs106

- Potentiometer316

- Resistor0

- SCR/Thyristor29

- Semiconductor ICs0

- Solenoids and Electromagnets2

- Transistor0

- Triac29

- DIY Learning and Robot Kits

- Drone Parts

- 3D Printers and Parts

- Battery, Chargers And Accessories

- Development Board

- Motors, Drivers, Actuators

- Displays

-

Sensors

- Biometric, Rotation and Current10

- Distance Sensor4

- Flame Sensor2

- Hall Sensor4

- IMU, Accelerometer, Magnetometer and Gyroscope9

- Load, Pressure, Flow and Vibration Sensor18

- Motion, Light and Sound Sensor41

- Sensor Kit2

- Temperature, Humidity, Gas & Environmental Sensor23

- Thermoelectric Peltier Cooler and Heating Elements3

- Electronic Modules

- Wires and Cables

- Workbench Tools

-

Electronic Components

- Job Opening

All

- All

- 3D Printers Parts and Accessories

- Development Board

- Arduino Board and Accessories

- AVR Development & Breakout Board

- Raspberry Pi Board & Accessories

- Wireless Controller Board and Module

- Display

- LCD Display

- LED Dot Matrix Display

- OLED Display

- Seven Segment LED Display

- DIY Learning and Robot Kits

- Robot Kits and Parts

- Drone Parts

- Drone Flight Controller and Accessories

- Drone Frame, Speed Controller (ESC) and Accessories

- Drone Kit

- Propellers

- Other Blade Fans

- Propeller Accessories

- Electronic Components

- Bread Board and Zero PCB

- Capacitor

- Capacitor Reel

- Polyester Box Capacitor

- SMD Capacitor

- Through Hole Capacitor

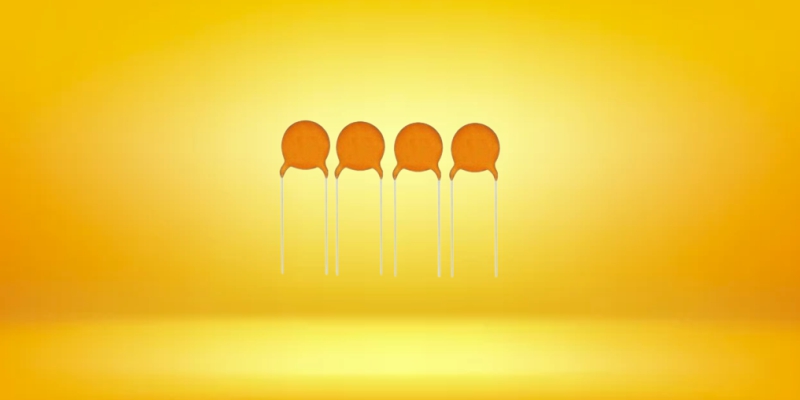

- Ceramic Capacitor

- Electrolytic Capacitors

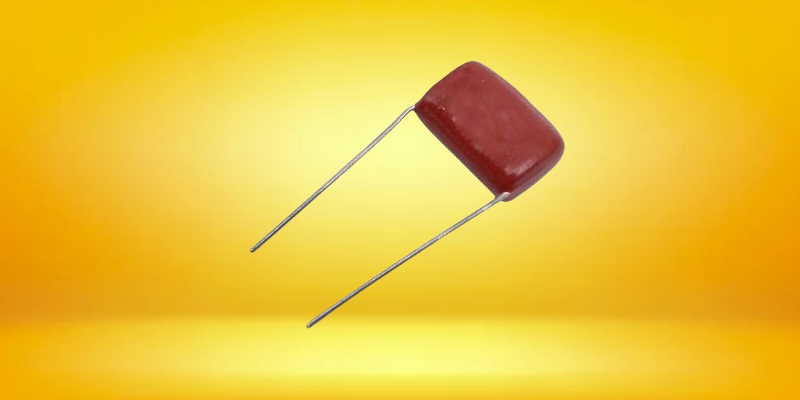

- Polyester Film Capacitor

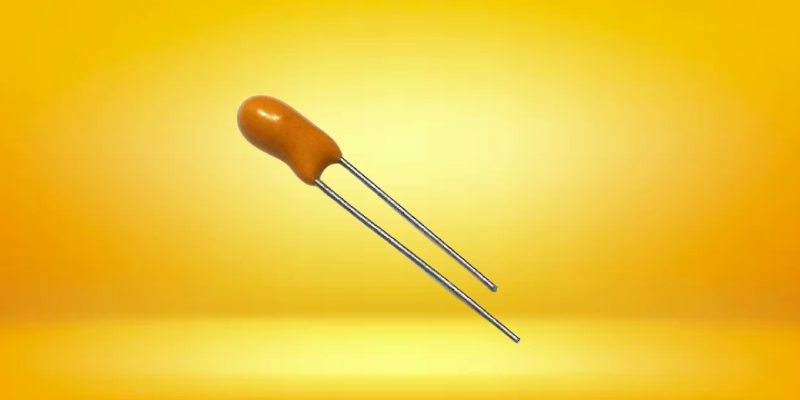

- Tantalum Capacitors

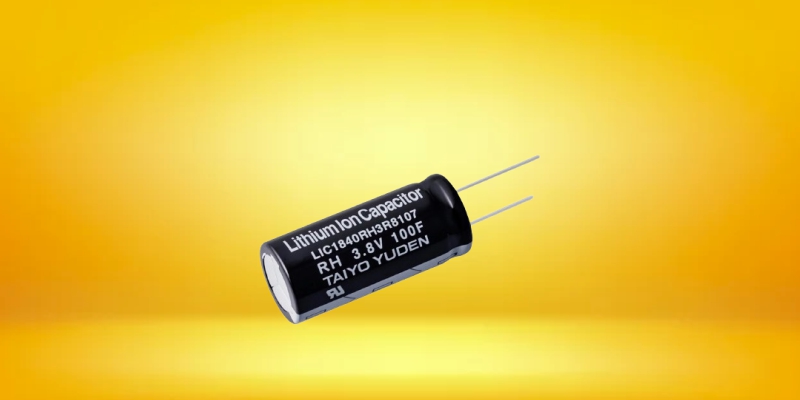

- Through Hole Super Capacitors

- Crystal Oscillators

- DIP (Through-Hole) HC-49 Crystal

- SMD HC-49 Crystal

- YXC YSX Series SMD Crystal

- Diodes

- Diodes and Bridge Rectifiers (DIP)

- Diodes and Bridge Rectifiers (SMD)

- Photo Diodes (DIP)

- SMD Diodes Reels

- Zener Diodes (DIP)

- Zener Diodes (SMD)

- Electronic Switches Button and Keypads

- Fuse and Holders

- Car Blade Fuse

- Fuse Holders

- Glass Fuse

- PPTC Resettable Fuse

- Heat Sinks

- IGBT

- Inductor

- DIP Inductor

- SMD Inductor

- Wire Wound Inductors

- LEDs and Indicators

- LEDs (SMD)

- LEDs (Through Hole)

- LEDs-Holders/Indicators

- Pilot Lamp Indicator

- Magnet

- Ferrite Magnet

- Neodymium Block Magnets

- Microcontroller ICs

- MOSFETs

- Potentiometer

- Resistor

- LDR

- Resistance Network

- Resistor Reel

- SMD Resistor

- Thermistors/Varistors

- Through Hole Resistor

- Wire Wound Resistor

- SCR/Thyristor

- Semiconductor ICs

- BT, RF and WiFi ICs

- Clock, Timer and Counter ICs

- Comparator ICs

- Converter ICs

- Driver ICs

- Encoder ICs

- IC Base

- Interface ICs

- Logic Gate ICs

- Memory ICs

- Operational Audio Amplifier ICs

- Optocoupler ICs

- Power Management ICs

- Sensor ICs

- Solenoids and Electromagnets

- Transistor

- 2N Series Transistors

- 2S Series Transistors

- BC Series Transistors

- BD Series Transistors

- BF Series Transistors

- BU Series Transistors

- MJ Series Transistors

- Other Transistors

- PN Series Transistors

- S-Series Transistors

- SMD Transistors

- TIP Series Transistors

- Triac

- Electronic Module

- Audio

- Audio Module / Amplifier

- Buzzers and Speakers

- Power Supply

- SMPS Power Supply

- Transformers

- Relay Switch and Electronic Module

- Solar Panel and Controller

- Voltage Regulator

- Boost Converter (Step-Up)

- Buck Converter (Step-Down)

- Motor, Driver, Actuators

- Brushed DC Motor

- 25 GA Motor

- BO Motor

- Center Shaft Gear Motor

- Johnson Geared Motor

- N20 Micro Gear Motor

- Other DC Motor

- RS 50 Geared Motor

- Side Shaft DC Gear Motor

- Cooling Fan

- Drone Motors

- Other DC Motor

- Planetary Gear Motor

- Pump

- Servo Motors

- Vibration Motor

- New Arrivals

- Others

- reuse-sku

- Shop By Brands

- Uncategorised

- Wires and Cables

- Heat Shrink Tube & Sleeve

- Jumper Wires, Connectors, FRC and Interfacing Cables

- Workbench Tools

- Measuring Instruments

- Nuts Bolts, CSK Screws, Spacer and Standoff

- RC Car, Caster and Heavy Duty Wheel

- Tools

- Sensors

- Biometric, Rotation and Current

- Distance Sensor

- Flame Sensor

- Hall Sensor

- IMU, Accelerometer, Magnetometer and Gyroscope

- Load, Pressure, Flow and Vibration Sensor

- Motion, Light and Sound Sensor

- Sensor Kit

- Temperature, Humidity, Gas & Environmental Sensor

- Thermoelectric Peltier Cooler and Heating Elements

- Battery, Battery Chargers And Accessories

- Battery Accessories

- Non Rechargeable Battery

- Rechargeable Battery